I had been writing this post for here but Bell of Lost Souls has a hobby article shopping spree contest going on so I'm posting it both places. If you want to support my plastic crack addition please vote over on the Bell of Lost Souls lounge for this hobby thread. It will be broken into a couple seperate posts there with all the same images (linked from here) and dialog.

Well I was going to do this for my personal blog but figured

I might as well do this on Bell of Lost Souls as well if there is a chance to

win some free miniatures. Ah the power

of free.

I’m a big believer in free, or at the very least cheap, so I’m

going to show you guys a pretty easy and relatively cost effective way to make

some miniatures icons for your armies.

We are going to be using a single piece of software for

this, Sketchup. Sketchup has a free and

a paid version, anything the paid version can do can also be done with the free

version and a community created plugin. This makes sketchup very versatile even

with out paying the 500 bucks for the “professional verson”. In the

past I’ve covered plugins on my blog to help people track down what they need

to maximize their efficiency in sketchup.

You can find the blog post here,

http://dynath.blogspot.com/2012/03/building-miniatures-in-sketchup.html.

We will also be using an 3d printing service called

shapeways found here,

http://www.shapeways.com.

Shapeways is a community and sales site centered around customer created 3d

printable objects. The price of shapeways products is set by the person that

makes the object but ordering your own products for yourself will only cost you

the actual production costs. While 3d printing can become quite expensive for

large objects, small items like miniature bits are easy to make and cheap to

order.

In this I’m going to show you how to make the master model

for an icon plate. This works very well

for space marine armies but could also be used for any force icon.

First of course download and install Sketchup. I’ve also

installed all of the plugins found in the blog post I’ve linked above.

Step 1: the background

Icons are easiest to mount if you put them on a

background. In this case I’m going to

build a basic base that I can reuse. I

start by making a square. Using the

rectangle tool I drag out a square, when dragging the dashed line across the

center tells you when you are making a square or a golden section.

If you look at the bottom right corner in the info box you’ll

see the size of the item I’m working with.

The square I started with is about 1000 millimeters. This is too small. Sketchup is designed to work with architecture

so it can have some trouble when you make really small items. So we need to work at a larger scale and then

shrink the model down before we export it.

I like to work at 1000 times the final size. It’s is large enough I

rarely have problems with geometry and the math for scaling is easy to figure

out.

Here I’ve put some measuring lines on the square so we can

see the size. Then, with the square

selected, I’ve selected the “Scale Tool”.

This puts little green handles around the sides of the object. Then by dragging I can resize the

square. In this case I wanted to make a

square that when output will be 15mm on each side. So I drug the scale handle until the square

has a size of about 15,000mm on each side.

Precision is not totally necessary but it helps.

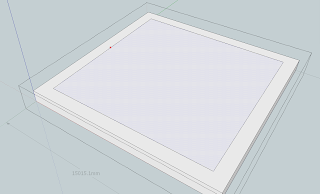

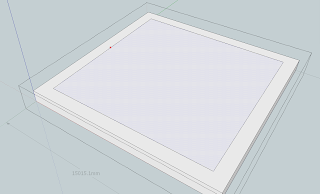

Well we have a nice two dimensional square but we need to

have some depth to make a 3d model. So

we are going to choose yet another tool, the “Push/Pull tool”. If we choose that tool, and then left click

on a flat surface it can push or pull the surface out giving it thickness. Watch the bottom left corner of the screen to

determine how far you are pulling it. I

want the plate to be about 1mm thick so I’m making the larger model 1000mm tall

approximately.

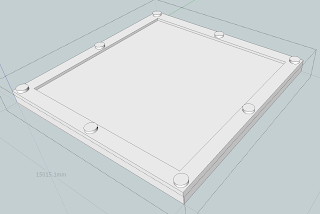

Now we have a nice square background for our model. We can select it and make it a group so it

doen’t get lost. Of course GW put some

of their icons (on the drop pod sprues) on squares and circles and they are

pretty boring so let’s fancy this up a bit.

Double click on our group to open it up.

Then select the “offset tool” this lets us click on a surface to offset

a line inside that surface. In this case

I want to drop a line about 1000mm from the outside edge of our square.

Now I’m going to use the “Push/pull tool” to push the

surface in about 200mm. this will make

the total thickness in the middle of the plate about 0.8mm when done. Shapeway has different materials with

different minimum thicknesses so be aware of what your limits are for the

material you want to print in. I usually

use Frosted Detail. It has lots of detail for miniatures and a 0.5mm minimum

thickness so the thickness I just set it at is about perfect for a sturdy

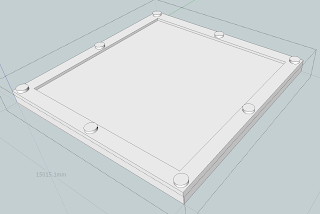

plastic plate. Now lets add some rivits

along the outside edge. If you hover

over the center of a line or shape a white dot will appear marking the

center. You can click on it with a tool

to use it as an anchor. You can do the

same for existing points where a green dot will appear. So using the “Line tool” find the center and

corners of the outside edge and drag lines in so you have reference points. Then switch to the “Circle tool” find the center point of your lines and you

can use it as the center of a circle.

Then using the “Eraser tool” you can remove the reference line. Lastly go back to your “Push/Pull tool” to

pull the circles out making 200mm tall rivets around the rim of your plate.

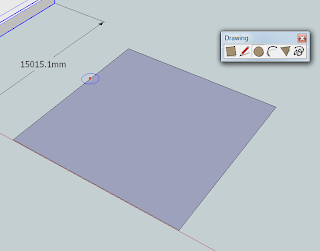

Step 2: The icon

So now we have our base plate, it’s scaled correctly, and it

looks fancy. So now we need an icon to

put on the plate. Sketchup has a bunch

of basic drawing tools you can use to draw shapes. Here I’ve drawn a new square and I’ve pulled

out the drawing tools so you can see the pallet.

Aside: I will warn sketchup’s

drawing tools are very limited so you might be inclined to use a separate

program to design your icon. Your best

option for making geometry from an external file is to use a vector art software

that can export DXF or DWF files. These are specific 2d vector formats Sketchup

can process. Doing an image in MS paint

won’t be any help. I own Adobe Illustrator

which works for this but is very pricy. There are a number of free alternatives

out there, check out Wikipedia or ask for recommendations from graphic artists

if you can. An added advantage of separate programs like Illustrator is that

they can often convert a raster image to a vector allowing you to use your own

sketches or found images as the basis for your icon.

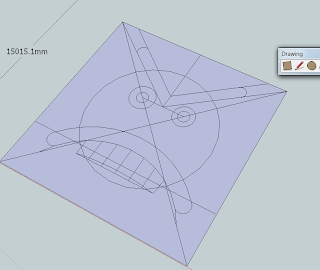

We now need to make our icon. I’m a huge fan of the custom

space marine chapter “the angry marines” so let’s make an angry marine icon. Angry faces aren’t hard to make, they start

with a circle. So find the center of

your square by drawing an X from corner to corner then draw out a large

circle. Using the X as a reference point

draw in eyes. Then add horizontal reference bars to draw out a wide V on the

forehead as a brow, and then a wide curve on the lower half as a frown. I’ve added teeth hanging down below the frown

to make it look meaner. Below you’ll

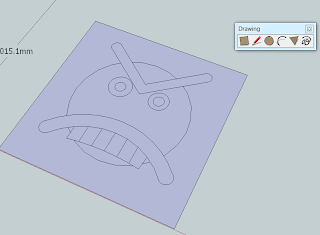

find images with my reference lines and after I’ve removed them.

The angry marines icon isn’t really clever or detailed just

a very angry, sort of goofy looking face.

Making your own custom icon might require a lot more detail. When working on an icon remember to think in

3 dimensions. All your lines have to

have thickness and form a picture that can be made in relief. So if you look at, say the lines separating the

teeth I drew, you will notice they won’t come out in 3d. You might have to work on that a bit to get

things to come out how you want. In this

case I’ll go to the offset tool and shrink the teeth a bit to make them work as

intended.

Now we can use the “Push/Pull tool” to give the icon

depth. I work from the deepest part down

so I’ll pull the brow and frown out first. Then the eyes and teeth. And lastly

the face itself. The 3d model is now a

relief all that’s left is to cap the bottom of the relief which is currently

open and then remove any excess geometry.

Adding a line at the bottom of the relief will seal the model and you

can erase excess lines around the outside of the model.

On a more complex icon you might want to make each of these

parts a separate piece so you can move them around and scale them separately. This can be necessary when working in

specific circumstances such as when making icons on rounded surfaces. In those instances you’d draw each level of

the relief separately. Like show below, then pull each one out to give them

depth. Once layered on top of each other

it’s no different than building them as one piece.

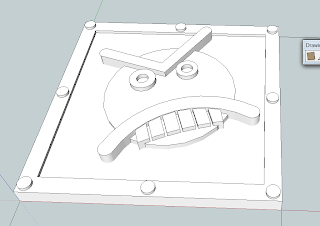

Step 3: put it all together

To complete our icon plate just put our relief icon on top

of our base plate. This gives us the 3d

model we want of an icon plate suitable for slapping on a vehicle or building.

At this point we have a fantastic relief of the icon on a

base plate but it’s 1000 times the size we need it at. So again we use the “scale tool” this time

selecting the entire completed icon and then the “scale tool”

Now we need to export it. Most 3d printing sites need a

specific format of output file, usually Stereolithography files or STLs. Shapeways is no exception. For that we need to use an STL export plugin

provided by the Sketchup community. You can find it linked from my earlier blog

post. Select your completed model and go

to “Plugins”. Now choose “Export STL

file”. It will launch a dialog box to choose the size of your stl, select “millimeters”

and it will then ask you where to save the file.

Step 4: Shapeways order

If you’ve done everything the file you exported will be

print ready. You can start a shapeways account and upload the file there to

order for yourself. If you get an error when you try to purchase

shapeways will give you feedback on what to fix. I’ve done some advise articles

on this process on my blog and the shapeways community is fantastic for helping

people sort out issues.

If you are interested later this week on my blog “dynath.blogspot.com”

I will be demonstrating how this same process can be used to make other items

such as shoulder pads.

Thank you and I shamelessly say “Vote for me”

Disclaimer: Warning reproduction of copyrighted designs

constitutes intellectual property rights infringement. I neither condone nor

suggest that you use these methods for such purposes. I am not a representative of Trimble Inc.

owners of Sketchup and all associated marks nor a representative of

Shapeways.com owner of their associated marks.

Nor, and I can’t stress this enough, am I a representative of Games

Workshop or representing their interests.